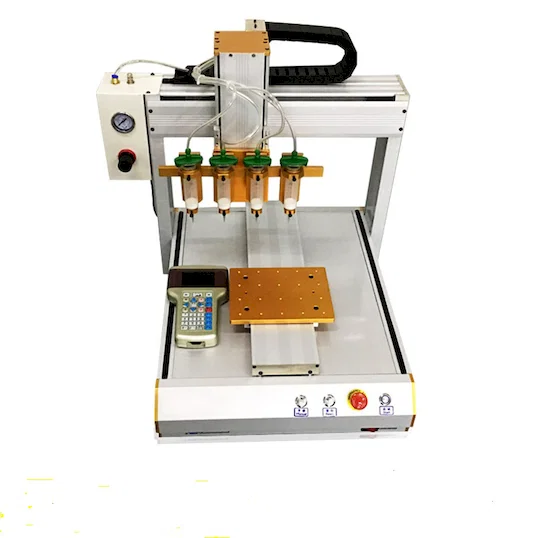

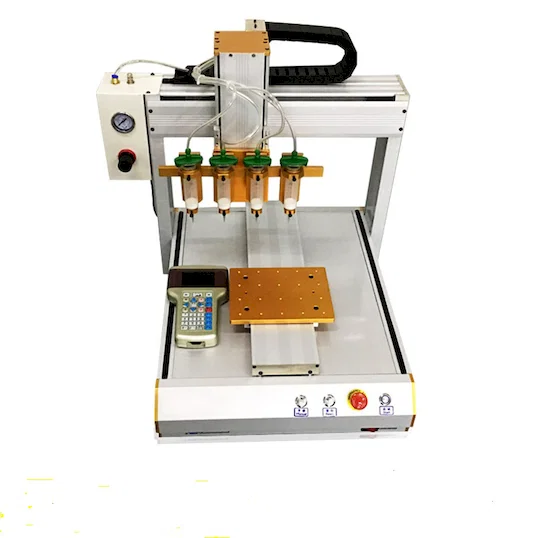

全自動點膠機 智能視覺定位點膠 WPM-332

產品型號: WPM-332

規格參數

自動點膠機,自動旋轉點膠機器人,4軸點膠機器人點膠機,噴膠機調壓閥:調節注射器內部壓力,壓力調節範圍為0.05-0.9MPa;調節時先拉出旋鈕,順時針旋轉增加,逆時針旋轉減少,調整后壓迴旋鈕。控制器開關:控制箱內的電源開啟或關閉。Y 軸滑塊:驅動基板來回移動。壓力表:顯示調節後的壓力。手動上膠按鈕:按下按鈕,將針頭出膠;鬆開按鈕,然後停止膠水。X 軸:控制指標向左和向右移動。Z 軸:控制指標上下移動。參考板:用於放置工件或夾具。Y 軸:控制參考板來回移動。底座:內部用於安裝電氣控制系統。重置開關:通過此開關,可以暫停正在運行的程式並返回源站。機器複位后,可以對示教進行程式設計。對於夾具吊板,可以安裝注射器或點膠閥,具體程式應根據工藝確定。緊急停止按鈕:按下該按鈕時,程式將中止,設備立即停止。開始/重置/暫停按鈕:是開機時或緊急停止解除后的系統重置開關。複位後為設備運行開關,運行為暫停開關。- 立即詢價

English

English Malay

Malay Swedish

Swedish Finnish

Finnish Danish

Danish Norwegian

Norwegian Polish

Polish Greek

Greek