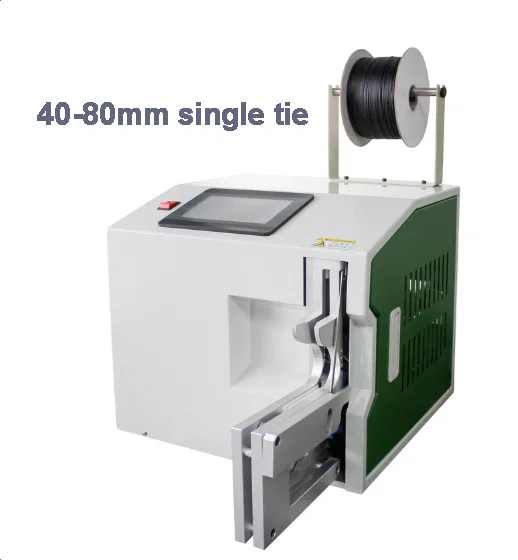

插座用卷取裝訂機 WPM-210

插座自動捲繞裝訂機 WPM-210 - 簡化您的電纜捆紮過程

介紹:

介紹用於插座 WPM-210 的捲繞裝訂機,這是一種高效的自動化解決方案,旨在優化您的電纜捆紮作。這款先進的 Coiling 裝訂機專為插座電纜、交流電源線、直流電源線、USB 電纜和各種其他傳輸線而設計。WPM-210 利用封裝的芯線扎帶創建整齊和安全的束,它還可以適用於膠帶和其他密封塑膠袋芯,提供卓越的多功能性。這台機器是減輕員工疲勞、大幅提高工作效率和節省扎帶材料成本的關鍵。

增強型電纜捆綁的主要功能:

用於插座 WPM-210 的 Coiling 裝訂機具有專為卓越性能和易用性而設計的功能:

-

多功能電纜相容性:這款 Coiling 裝訂機經過專業設計,可處理各種類型的電纜,包括交流電源線、直流電源線、USB 電纜、護套電纜、遮罩電纜、視頻電纜和 HDMI 高清電纜,確保在不同的產品線中具有廣泛的適用性。

-

自動繞線和打結作:員工只需將電線放在指定的埠上,機器就會自動執行繞線作。然後,將纏繞的電線放在接駁口即可啟動自動接紮,從而顯著減少手動步驟並提高輸送量。

-

減少疲勞和提高效率:使用 WPM-210 實現捲取和捆紮過程的自動化,可顯著降低員工的疲勞強度,從而實現持續的生產力並提高生產線內的整體工作效率。

-

電纜扎帶和材料節省:WPM-210 優化材料使用,與手動方法相比,WPM-210 旨在節省電纜紮帶,有助於提高成本效益和節約資源。

-

可自定義的綁定參數:該機器允許使用者設置綁紮線長度和每個扎帶的圈數,從而靈活地根據特定的電纜類型和所需的束緊度定製綁紮過程。

-

產量計數功能:集成的良率計數功能可準確跟蹤生產輸出,從而更好地監控和管理生產量。

-

帶文本顯示的 PLC 程式控制:採用使用者友好的 PLC 控制程式和文本顯示介面進行參數設置,使作簡單易學,最大限度地減少培訓時間。

-

可調間距和可更換夾具:WPM-210 專為多功能性而設計,具有易於調節的間距和可更換的固定裝置,可容納“8”形和圓形捆綁樣式,以及廣泛的捆紮尺寸,最大限度地提高了對不同產品需求的適應性。

跨行業的廣泛應用:

這款 Coiling 裝訂機非常適合製造或加工電纜和電線的各種行業,包括:

-

電子製造:對於在電子設備、元件和元件中捆紮電纜,提高組織和生產速度至關重要。

-

計算機及週邊設備生產:非常適合製造需要整齊捆綁和捆綁電纜進行內部佈線和外部連接的計算機和外圍設備。

-

Appliance Manufacturing: Ideal for organizing power cords and internal wiring harnesses in household and commercial appliances, ensuring neat and secure cable management.

-

Telecommunications Equipment Production: Suitable for bundling cables used in telecommunications equipment, contributing to organized and reliable wiring systems.

-

Automotive Wiring Harness Assembly: Adaptable for certain automotive wiring harness applications requiring coiling and binding of wires and cables.

-

Any Manufacturing Using Bundled Cables: Applicable across diverse industries where efficient and consistent coiling and binding of various types of cables and wires are required.

可靠性能的技術規格:

-

Model: WPM-210

-

Machine Type: Automatic Coiling and Binding Machine

-

Suitable Cable Types: AC power cords, DC power cords, USB cables, sheathed cables, shielded cables, video cables, HDMI high-definition cables, etc.

-

Core Type Compatibility: Encapsulated core twist ties, tape and other sealing plastic bag cores

-

Operation: Automatic winding and tying

-

Control System: PLC Program Control

-

Interface: Text Display for Parameter Setting

-

Adjustability: Binding wire length, number of laps, spacing, replaceable fixtures (for "8" shape and round tying)

-

Functionality: Yield Counting

結論:

Invest in the Coiling binding machine for socket WPM-210 to revolutionize your cable bundling operations. This efficient and versatile machine automates key processes, reduces labor costs, and improves product quality, making it the ultimate Coiling binding machine for maximizing your production efficiency and cable management. Contact us today to learn more about how the WPM-210 can transform your production line and elevate your manufacturing capabilities!

This machine is suitable for AC power cords, DC power cords, USB cables, sheathed cables, shielded cables, video cables, HDMI high-definition cables, and other types of transmission lines using encapsulated core twist-tied into a bundle, can also be used to tape and other sealing plastic bag cores. This machine can reduce employee fatigue strength, improve work efficiency, save cable ties, and so on. Employees simply put the wires on the port it will automatically wind, then putting these wires around the Norse mouth, the machine will automatically Norse. The machine can set the binding wire length and number of laps, and count the yield. The machine adopts a PLC control program, and text display for parameter setting, easy to operate. Adjusting spacing, and replacement of fixtures is very convenient, ("8" -shaped tying, tying round universal, large range of bundled, widely used.)

Parameters:

|

1

|

Power supply

|

AC220V AC110V

|

|

2

|

Power frequency

|

50HZ/60HZ

|

|

3

|

Rated power

|

120W

|

|

4

|

Winding length

|

Adjustable

|

|

5

|

Winding laps

|

Adjustable

|

|

6

|

Winding speed

|

Adjustable

|

|

7

|

Scope of application

|

Norse length

|

Norse diameter range

|

|

65-120mm

|

Φ4—Φ18mm

|

|

80-140mm

|

Φ8—Φ28mm

|

|

115-180mm

|

Φ18—Φ40mm

|

|

|

|

140-220mm

|

Φ28—Φ50mm

|

|

8

|

Norse laps

|

Can be set (recommended 3-6 laps)

|

|

9

|

cable ties

|

Packet core cable ties, cable ties of

coreless

|

|

10

|

protective device

|

Fuses, fault alarm shutdown

|

|

11

|

Size(LXWXH)

|

400x380x580mm

|

|

12

|

Total weight

|

40-72Kg

|

English

English Malay

Malay Swedish

Swedish Finnish

Finnish Danish

Danish Norwegian

Norwegian Polish

Polish Greek

Greek