使用 CE 認證的電線壓接外殼插入機實現完全自動化

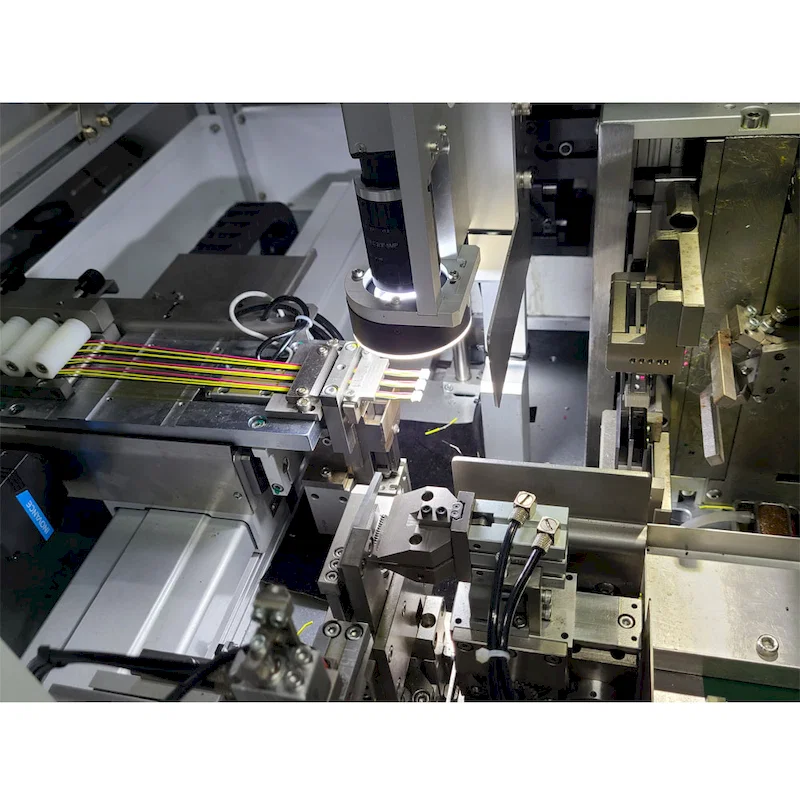

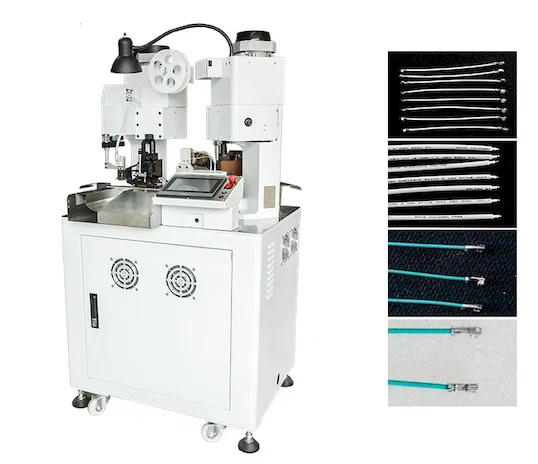

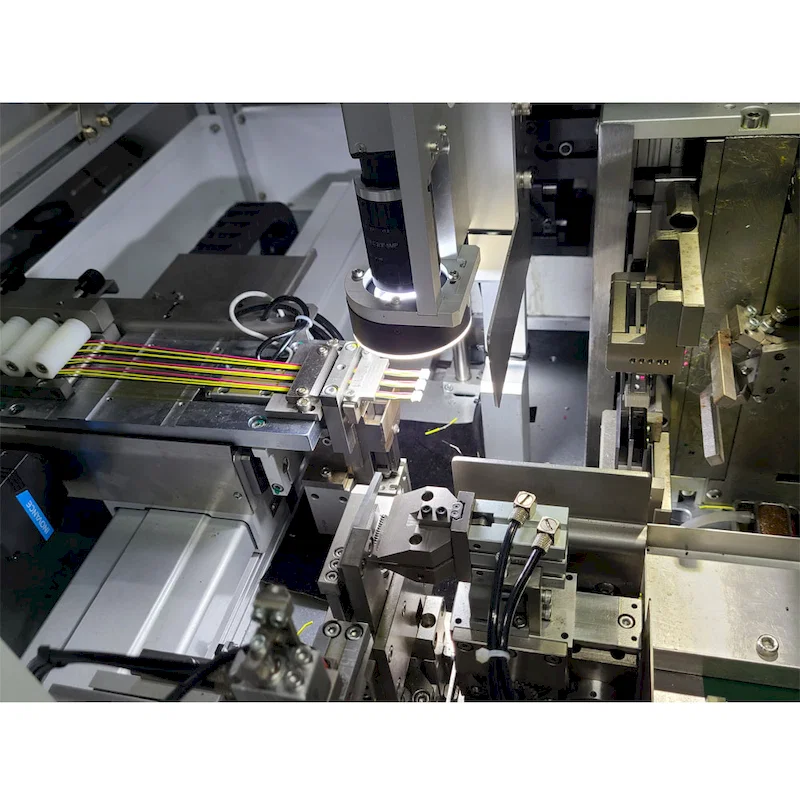

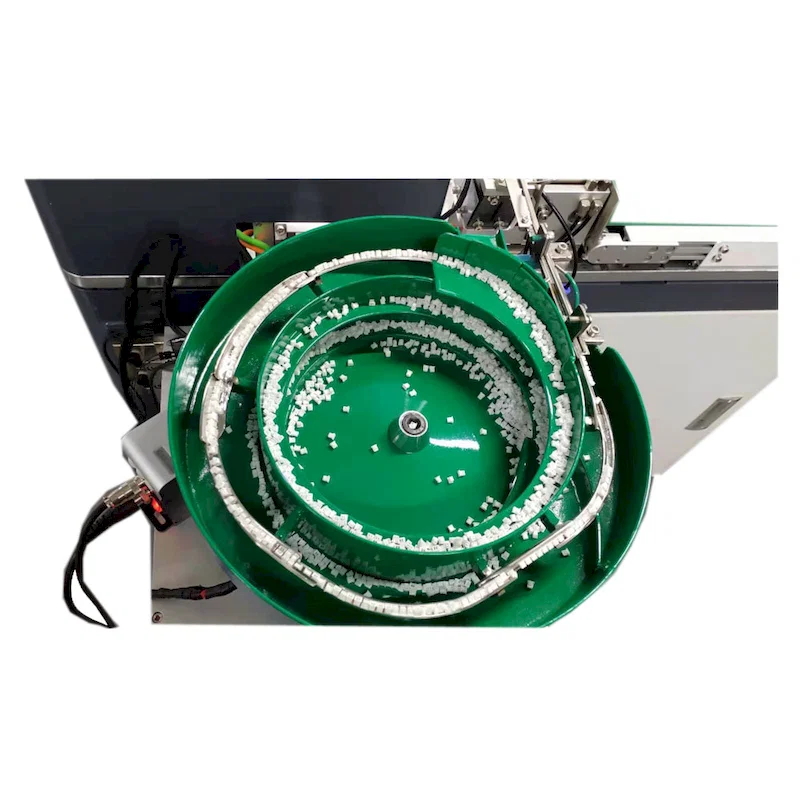

使用 CE 認證的全自動電線壓接和外殼插入機徹底改變您的線束元件,這是最大限度地提高效率和精度的終極解決方案。這種先進的機器,也稱為Wire Crimping Insertion Housing Machine 和 Automatic Wire Crimping Insertion Housing Machine,將多個複雜的過程無縫集成到一個高性能的單元中。從剪線和剝皮到壓接、電線壓接外殼插入、扭曲和鍍錫,這種一體化系統簡化了您的生產線並顯著減少了體力勞動。使用這種創新和可靠的設備投資於您的線材加工的未來。

除了單獨作之外,Wire Crimp Housing Insertion Machine 還提供完全集成的工作流程,旨在優化您的整個線束製造過程,確保一致的品質並最大限度地提高輸送量。

導線壓接外殼插入機的主要特點和優點:

1. 全自動多功能,效率無與倫比:

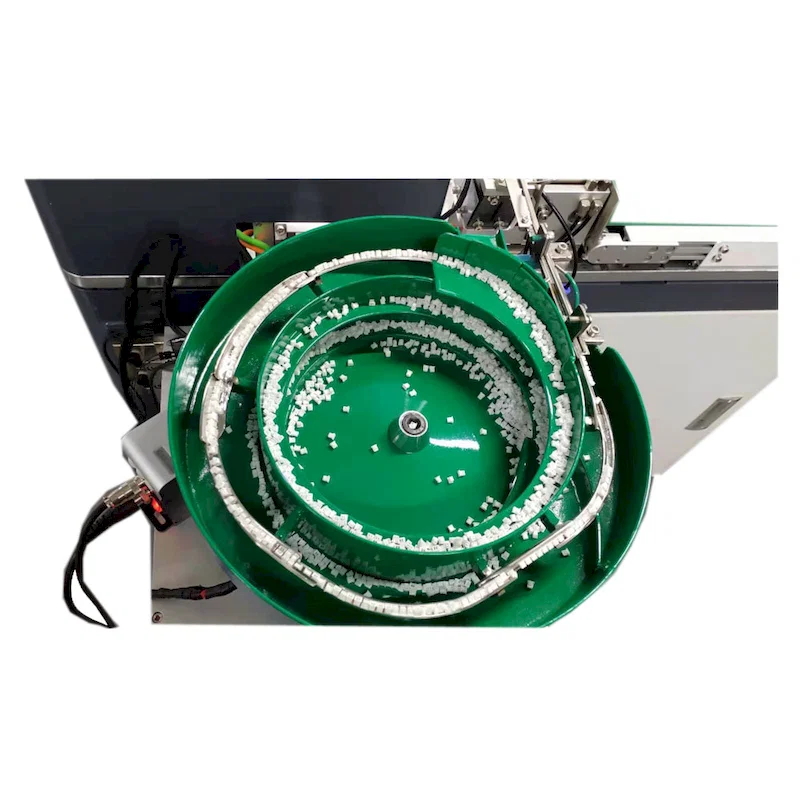

使用這款多功能機器體驗完全自動化。Wire Crimp 外殼插入機可熟練地執行一系列關鍵作:自動剪線、精確剝線、可靠壓接、精確外殼插入、電線扭曲和一致鍍錫。這種全面的自動化消除了瓶頸,減少了人工處理,並顯著提高了您的生產能力,為高效的線材加工設定了新標準。

2. 滿足各種線束需求的綜合加工能力:

使用這款功能強大的機器適應各種線束要求。電線壓接外殼插入機設計用於切割、剝皮、壓接和外殼插入,以及可選的扭曲和鍍錫,所有這些都在一個簡化的工作流程中完成。無論您需要基本的線材準備還是複雜的多階段加工,這台機器都能提供靈活性和功能,以滿足您多樣化的生產需求。

3. 可定制的功能以滿足您的特定要求:

憑藉其高度可定製的功能,根據您的確切生產需求定製機器。Wire Crimp Housing Insertion Machine 提供可選功能,包括:

-

單面切割、剝線、壓接和外殼插入

-

單面切割、剝離、扭曲和鍍錫

此外,定製支援擴展到各種加工配置,包括:

-

一端剝線、壓接和外殼插入;單端剝離

-

兩端剝線、壓接和外殼插入

-

組合功能:一端剝線、壓接和外殼插入;單端剝離、扭曲和鍍錫

-

加工相同長度的電線或所有不同長度的電線

這種廣泛的定製確保Wire Crimp Housing Insertion Machine 可以完美配置,以優化您的特定線束製造流程。

4. 強大的檢測功能,保證品質和可靠性:

通過集成的檢測功能確保始終如一的高品質輸出。Wire Crimp Housing Insertion Machine 具有全面的檢測系統,可監控:

-

無電線

-

打結線

-

缺少終端

-

缺少住房

-

低氣壓警報

-

Motor Abnormality

These robust inspection features guarantee smooth operation, minimize errors, and ensure only correctly processed wires with proper Wire Crimp Housing Insertion proceed in your production line.

5. High Production Capacity for Increased Throughput:

Boost your production output significantly. The Wire Crimp Housing Insertion Machine boasts a high production capacity, processing 530 - 650 cycles per hour. This impressive speed is achieved while processing multiple cables simultaneously (up to 6 cables with 2 pins each or 1 cable with 8-12 pins), making it an ideal solution for high-volume manufacturing environments and maximizing your return on investment in Wire Crimp Housing Insertion automation.

6. Advanced Control System for Seamless Operation and Data Management:

Experience intelligent automation with the PLC programmable control system. The Wire Crimp Housing Insertion Machine features a digitally controlled system allowing for precise parameter settings managed through file systems. The modular hardware design simplifies material changes and troubleshooting. Moreover, the equipment supports remote control via the internet, enabling real-time production monitoring, data generation, and export, offering unparalleled control and data accessibility for your Wire Crimp Housing Insertion processes.

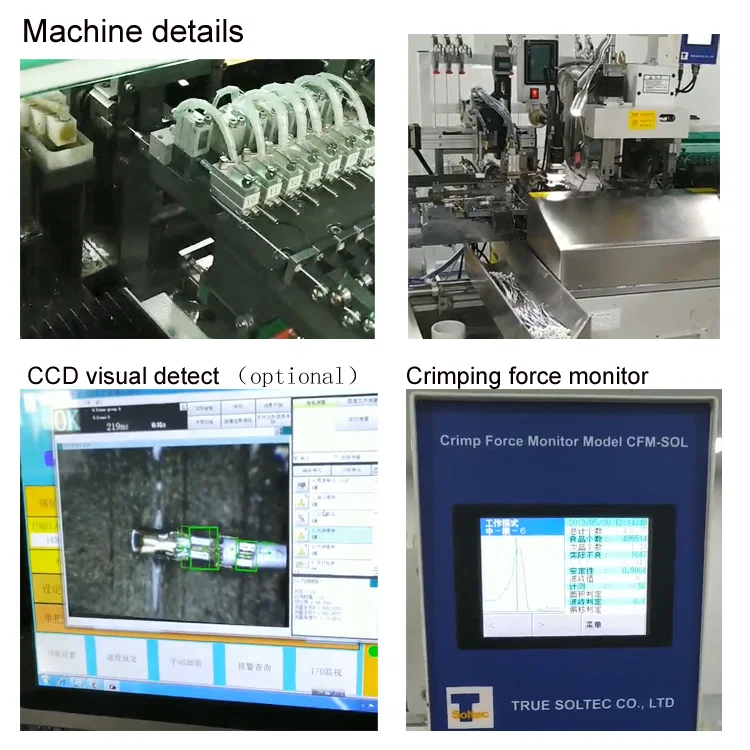

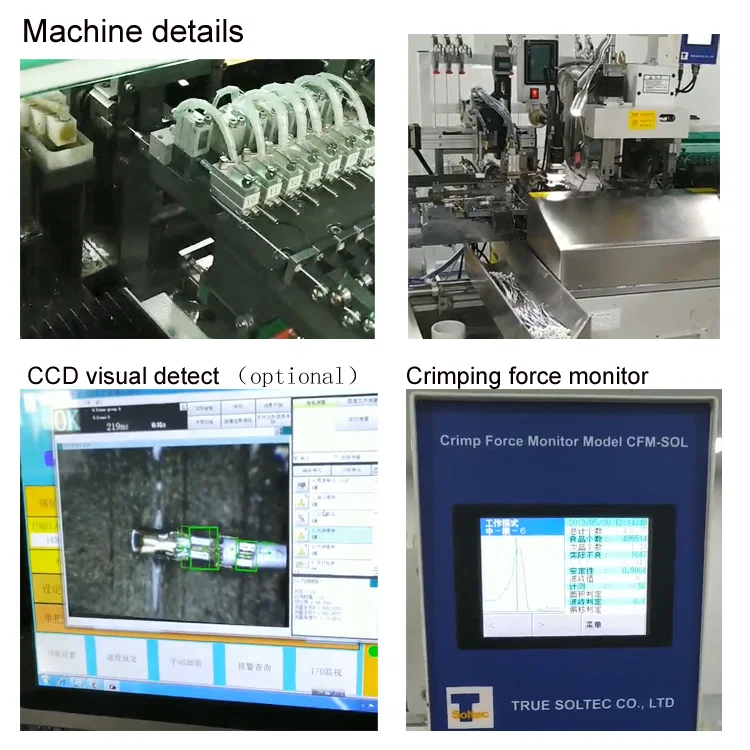

7. Optional Advanced Features for Enhanced Quality Control:

Further enhance your quality control with optional advanced features:

-

CCD Monitor: For visual inspection of terminal appearance, ensuring crimp quality.

-

Crimping Force Monitor: For real-time monitoring and control of crimping force, guaranteeing consistent crimp strength.

These optional features for the Wire Crimp Housing Insertion Machine provide an extra layer of quality assurance for demanding applications.

技術規格:

-

Model: Single-End Automatic Crimping, Housing Insertion, and Tinning Machine

-

Power Supply: AC220V, 1300W

-

Standard Functions: Cutting, Stripping, Single-end Crimping, Single-end Housing Insertion, Single-end Half-stripping, Twisting, and Tinning

-

Optional Functions: CCD Monitor, Crimping Force Monitor

-

Inspection Functions: No Wire, Knotted Wire, Missing Terminal, Missing Housing, Air Pressure Alarm, Motor Abnormality Detection

-

Production Capacity: 530 - 650 cycles per hour (processing 6 cables with 2 pins or 1 cable with 8-12 pins)

-

Cutting Length Range: 30 - 800 mm

-

Applicable Wire Gauge: 32 - 18 AWG

-

Rear Stripping Length: 1 - 9 mm (Half-stripping or Full-stripping)

-

Tinning Length: 1 - 9 mm

-

Required Air Pressure: 0.5 MPa

-

Machine Dimensions: 3.8 m (Length) × 1.8 m (Width) × 2.2 m (Height)

-

Machine Weight: 550 KG

Transform Your Wire Harness Production with the Wire Crimp Housing Insertion Machine Today!

The Wire Crimp Housing Insertion Machine is the intelligent investment for businesses seeking to optimize their wire harness assembly operations. Experience unmatched automation, precision, and versatility in your wire processing. Contact us now to learn more about how this revolutionary machine can transform your production line and give you a significant competitive advantage in the market for Wire Crimp Housing Insertion solutions!

English

English Malay

Malay Swedish

Swedish Finnish

Finnish Danish

Danish Norwegian

Norwegian Polish

Polish Greek

Greek