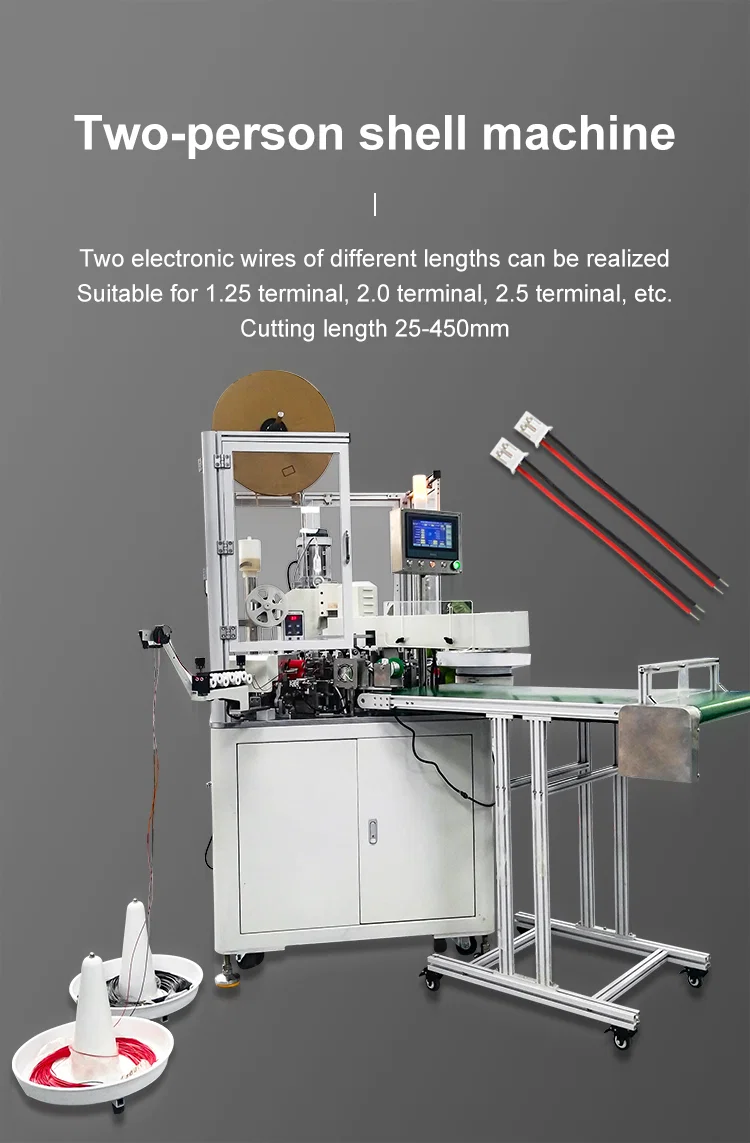

使用Wire Dip Tin Machine最大限度地提高線束生產的效率和精度,這是一種尖端的全自動解決方案。這種先進的機器,也稱為平行線插入殼式插頭機,專為簡化 2P 平行線的加工而設計。從單頭鍍錫到複雜的殼穿端子插入,這款多功能機器都能處理,顯著提高您的產量並確保一致、高質量的結果。Wire Dip Tin Machine 是電子線加工的理想選擇,是適用於要求苛刻應用的一體化解決方案。

這不僅僅是一台機器;它是一個完整的線材處理系統,旨在自動化複雜的任務,減少體力勞動,並保證滿足您所有線材準備需求的卓越性能。

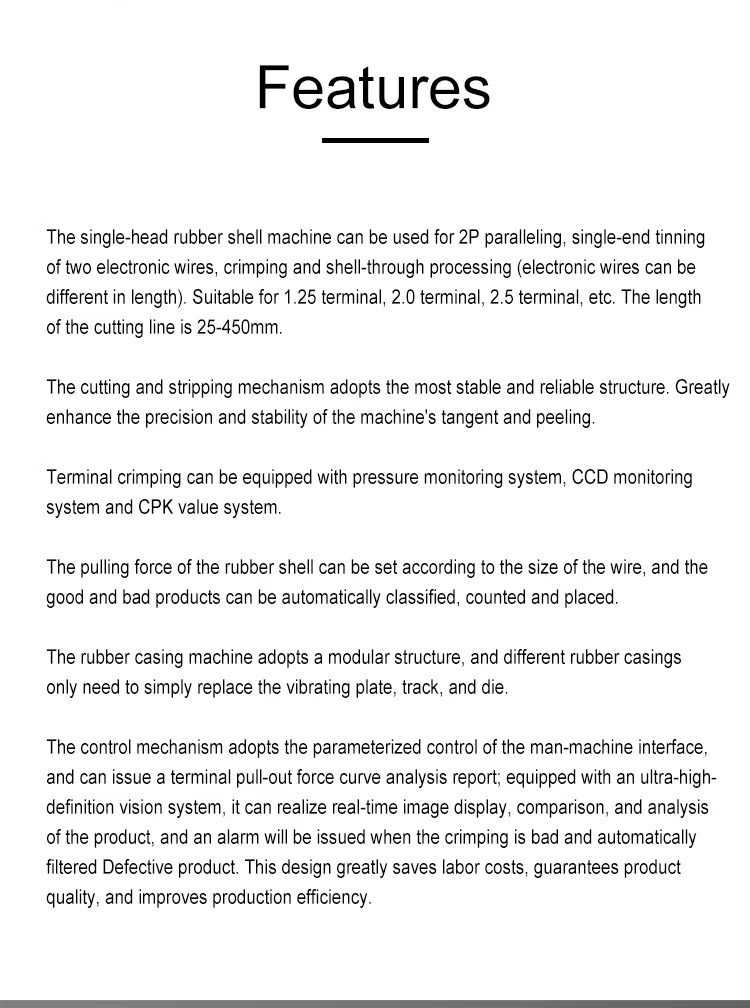

線浸錫機的主要特點和優點:

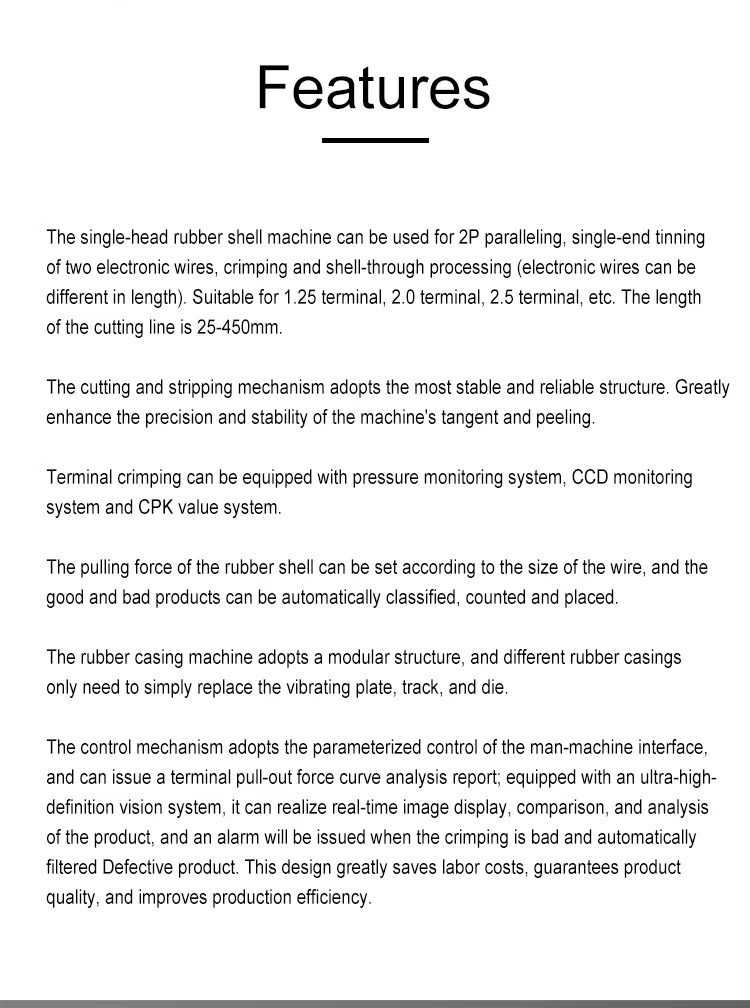

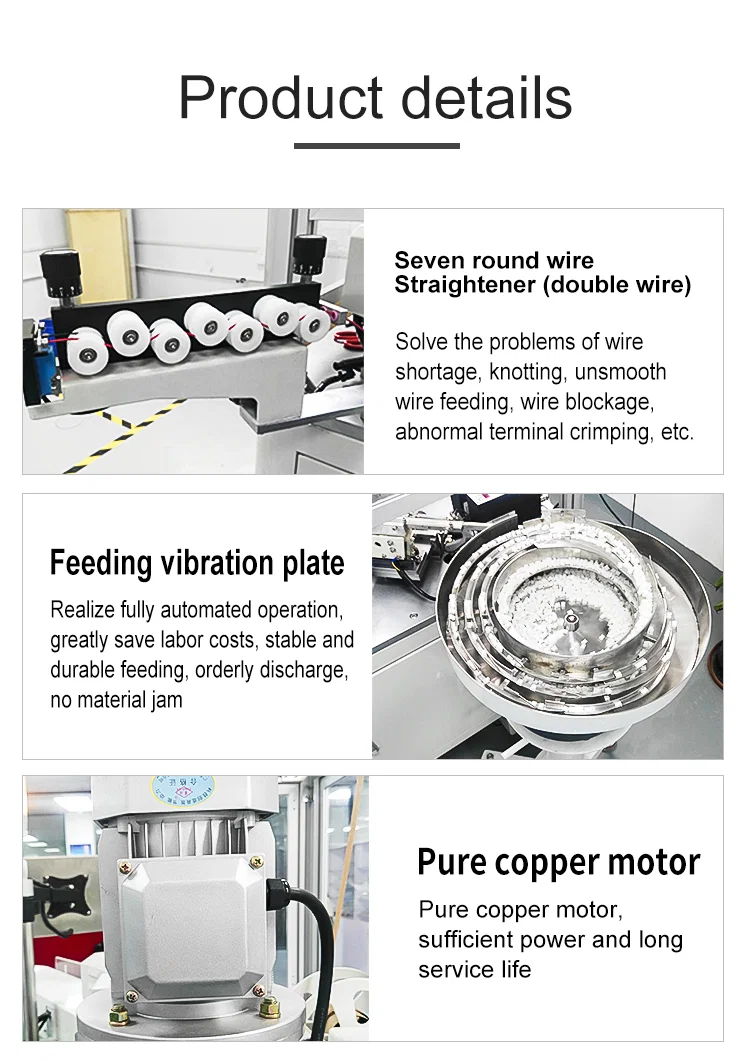

1. 全自動處理,無與倫比的效率:

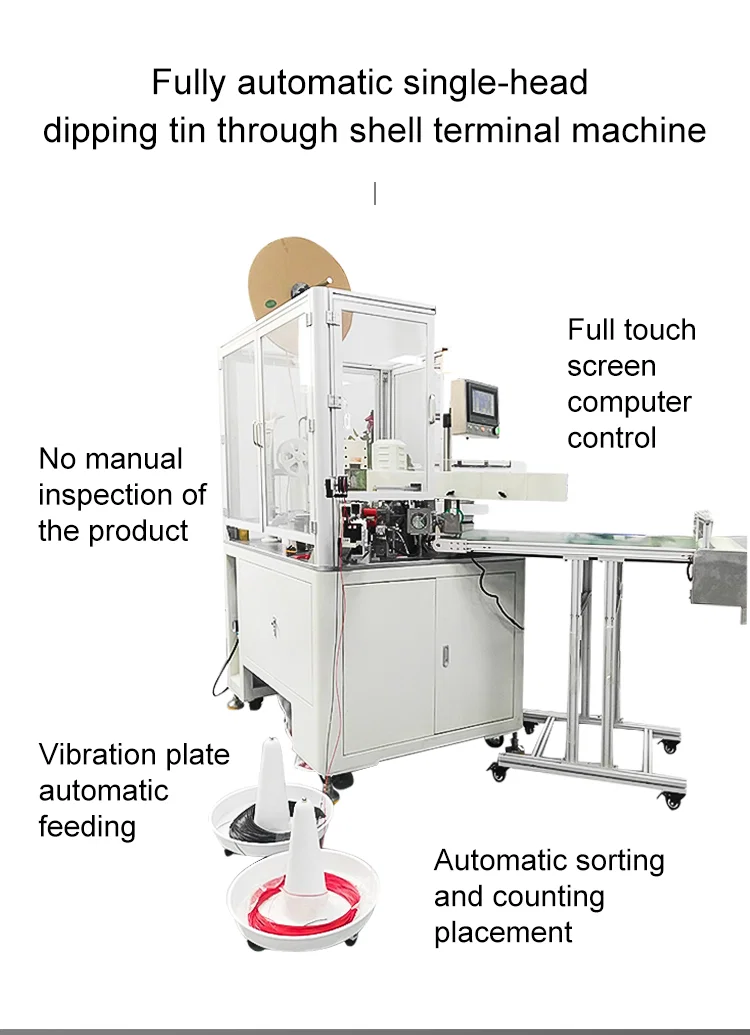

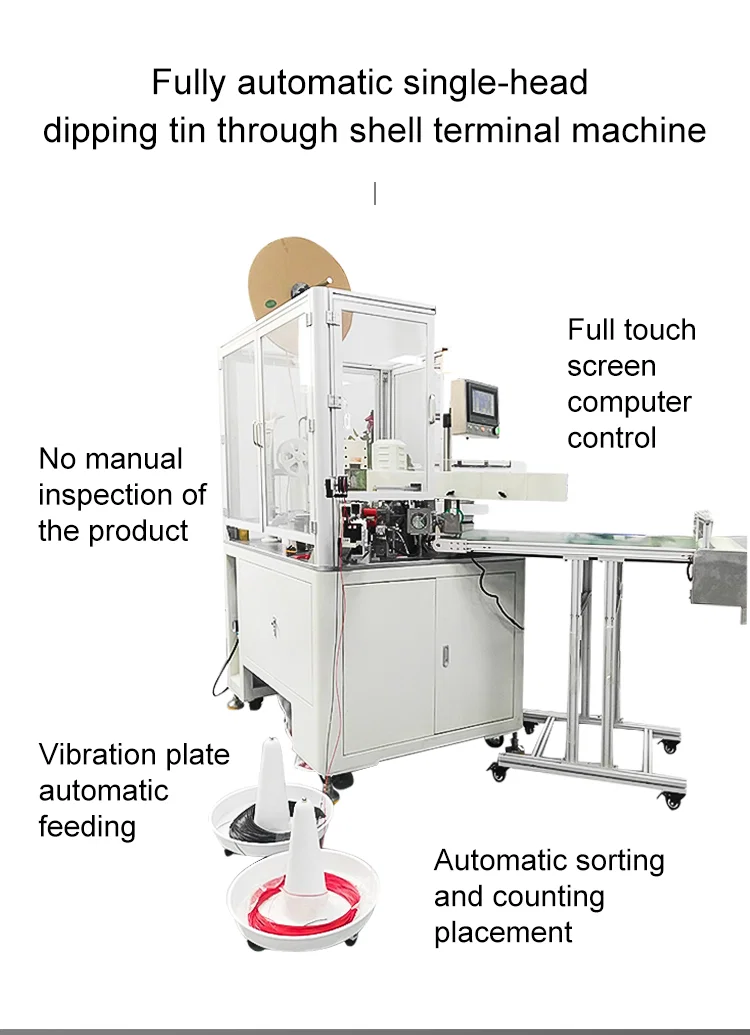

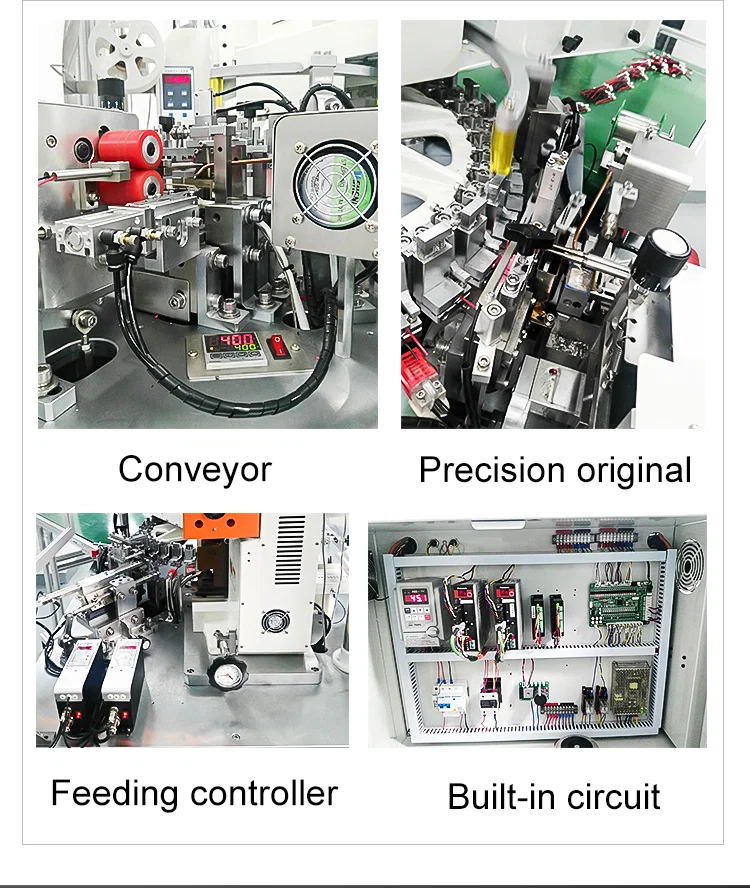

使用Wire Dip Tin Machine體驗真正的免提作。該機器自動化了每個關鍵步驟:自動送絲、精確切割、準確剝皮(剝皮)、一致的鍍錫、可靠的端子壓接(“擊中末端”)和安全外殼插入(塑膠插頭插入 - “磨損外殼”)。這種全面的自動化大大降低了人工成本,提高了生產速度,並最大限度地減少了錯誤,使其成為真正高效的Wire Dip Tin Machine。

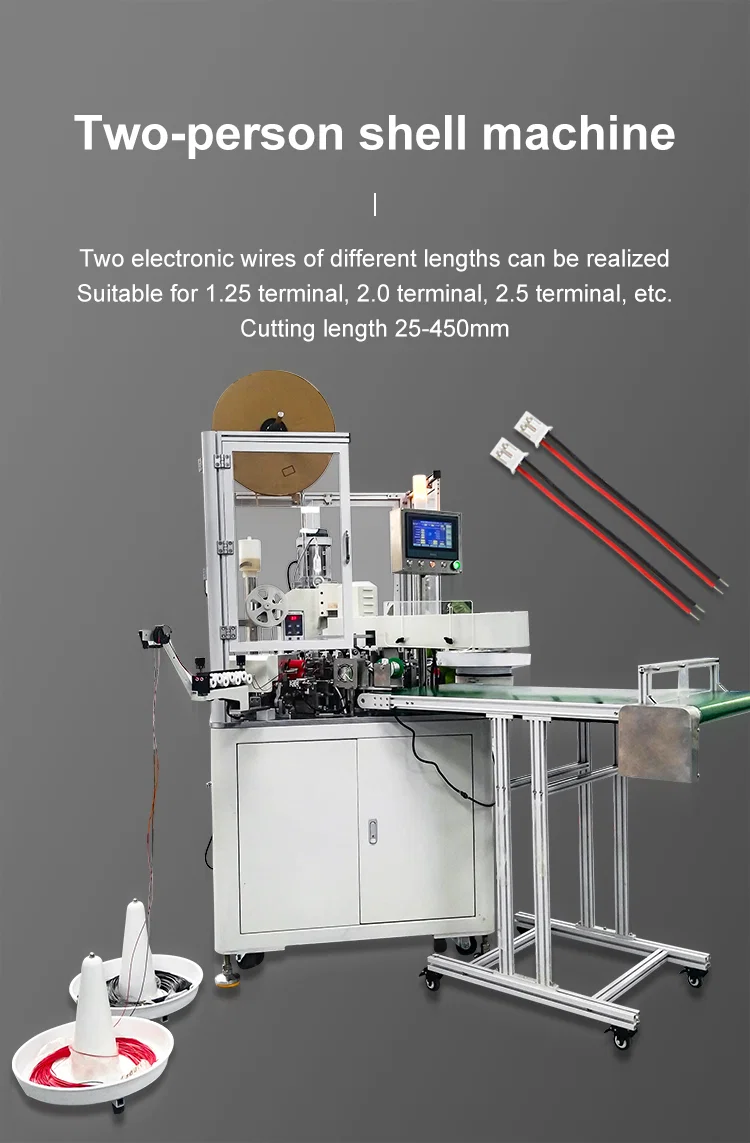

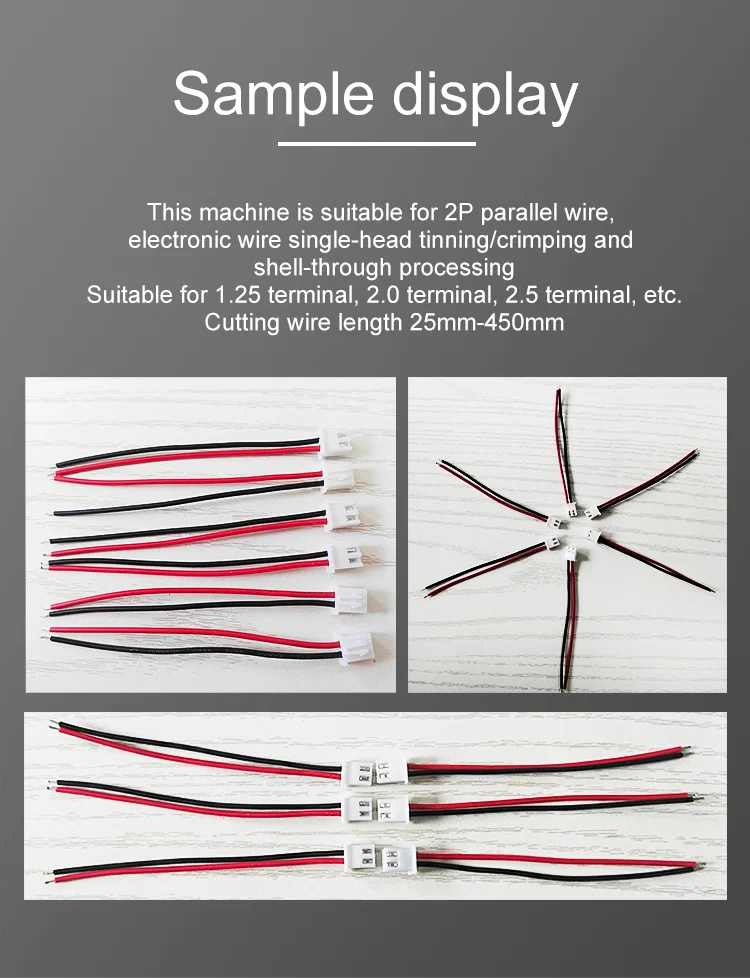

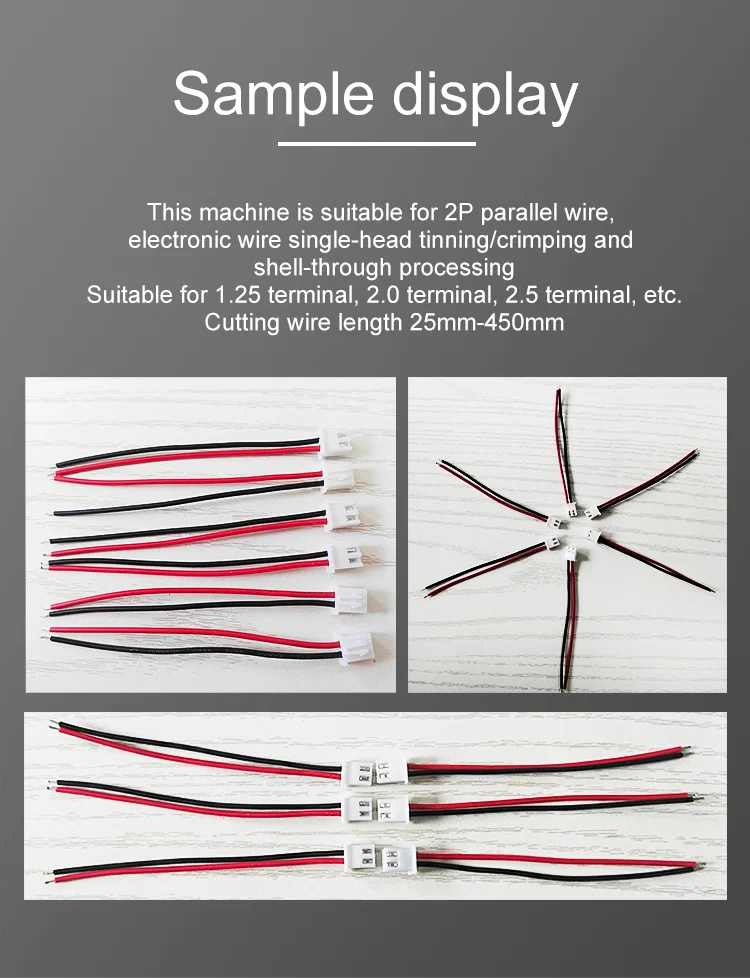

2. 多功能 2P 並行線處理,具有廣泛的端子相容性:

該機器專為 2P 平行線設計,具有卓越的多功能性。它擅長電子線的單頭鍍錫和壓接,並與一系列常用端子相容,包括 1.25、2.0 和 2.5 端子。可調節的切割線長度,從25毫米到450毫米不等,進一步擴展了其對各種應用的適應性,使其成為真正的多功能線材浸錫機。

3. 穩定可靠的切割和剝離機制,以實現精密作:

精度在線材加工中至關重要,而這台機器可以提供。Wire Dip Tin Machine 具有切割和剝皮機構,採用最穩定可靠的結構設計。這種堅固的設計確保了高度精確和穩定的切線和剝皮作,保證了後續工藝的一致和準確的線材準備。

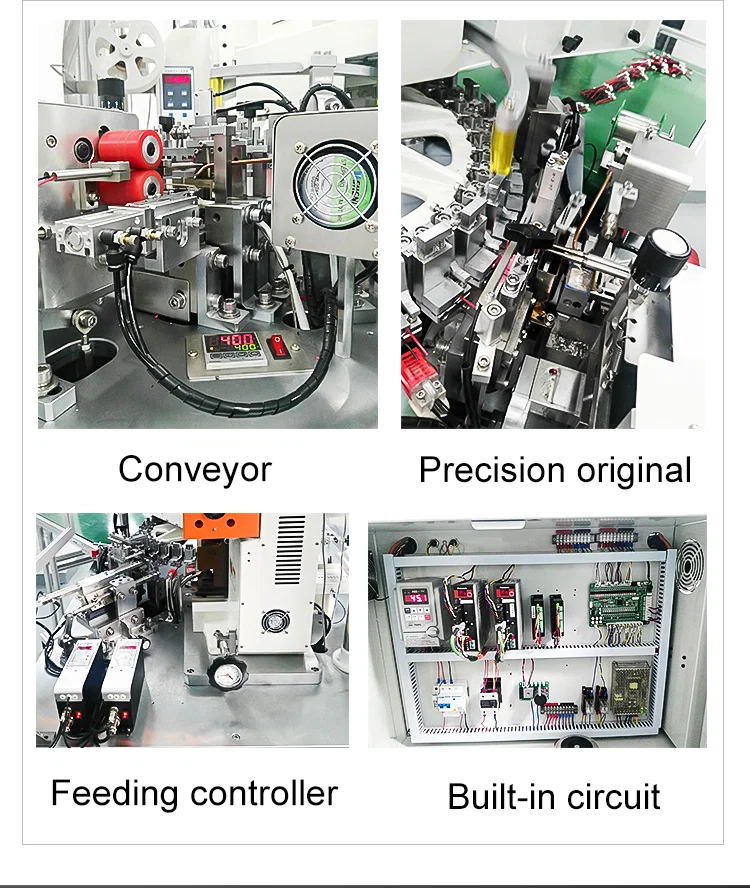

4. 帶監控系統的高級壓接質量保證:

確保每次都能實現完美的壓接。對於端子壓接,Wire Dip Tin Machine 可以配備可選的高級系統,包括壓力監控系統、CCD 監控系統和 CPK 值系統。這些系統保證了準確可靠的壓接,顯著提高了最終產品的品質和一致性,確保每個Wire Dip Tin Machine 的輸出都符合最高標準。

5. 智慧橡膠外殼處理和品質控制:

該機器集成了用於橡膠外殼加工和品質控制的智慧功能。橡膠外殼的拉力可以輕鬆設置,以匹配不同的線徑。此外,機器會自動對合格和不合格產品進行分類、計數和分離。這種智慧品質控制功能節省了寶貴的時間,並確保只有高品質、完美加工的線材才能在生產線中進一步進行,從而最大限度地提高Wire Dip Tin Machine 的效率。

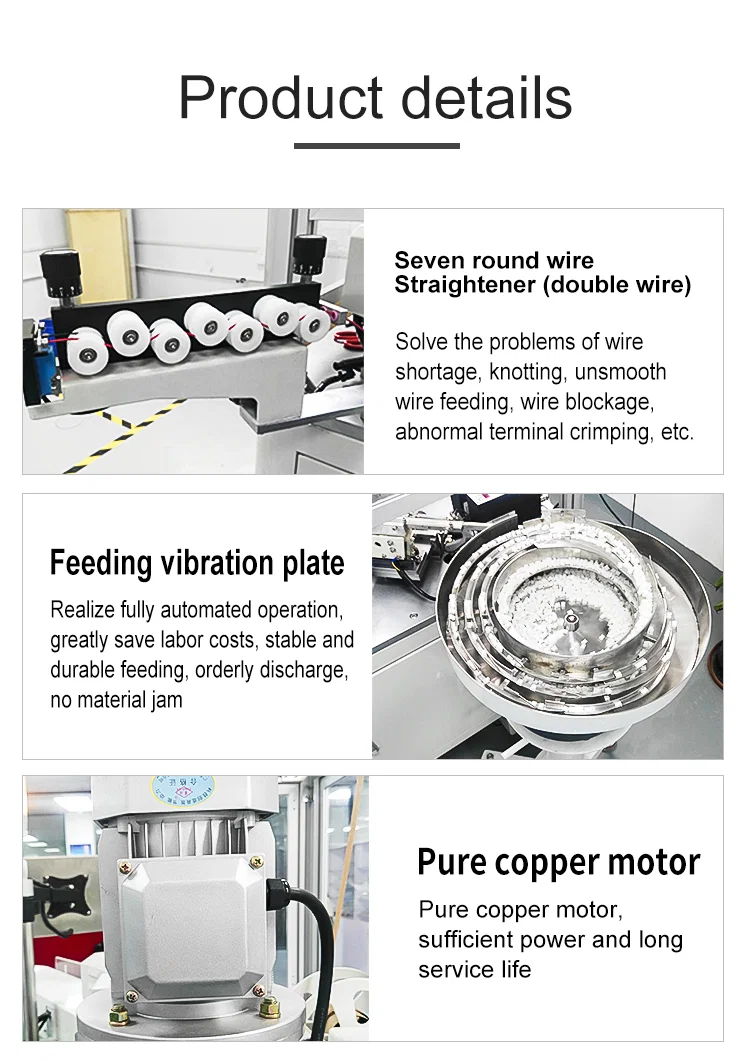

6. Modular Design for Easy Adaptation and Maintenance:

Adaptability is key to long-term productivity. The Wire Dip Tin Machine utilizes a modular structure. This smart design means that adapting the machine for different rubber casings is simple and efficient, requiring only a quick replacement of the vibrating plate, track, and die. This modularity ensures the machine remains versatile and easy to maintain across various production needs.

7. Advanced Control System with Real-Time Vision and Analysis:

Experience cutting-edge control and monitoring. The Wire Dip Tin Machine employs parameterized control via a user-friendly man-machine interface. It can generate a terminal pull-out force curve analysis report for detailed quality tracking. Equipped with an ultra-high-definition vision system, the machine provides real-time image display, comparison, and analysis of products. In case of bad crimping or other defects, the vision system triggers an alarm and automatically filters out defective products, significantly reducing labor costs, guaranteeing product quality, and dramatically improving production efficiency of the Wire Dip Tin Machine.

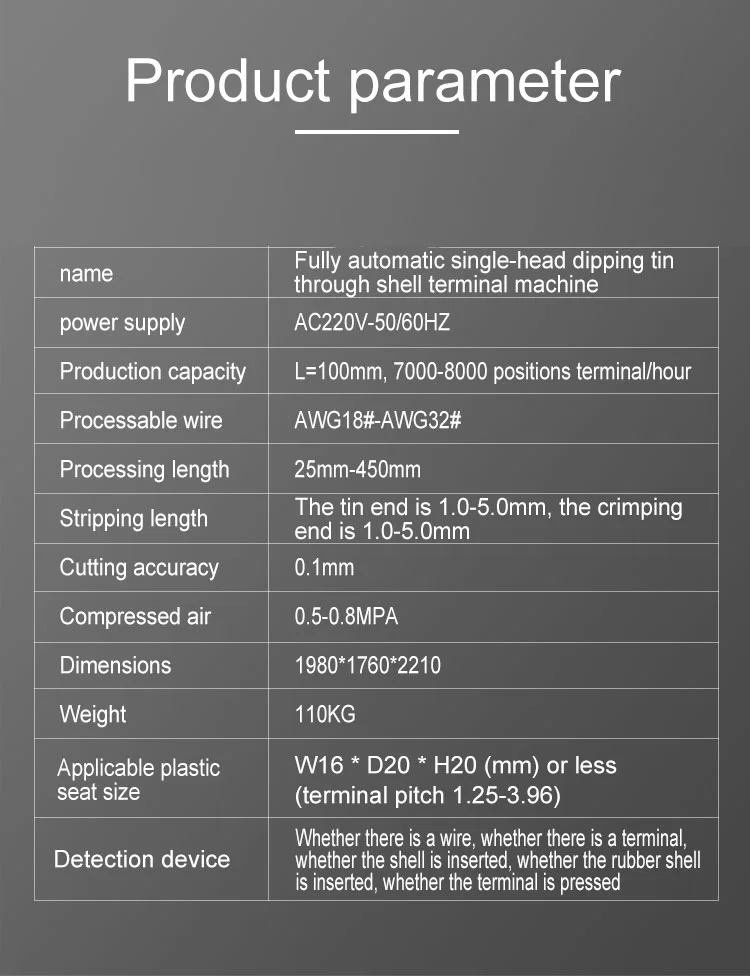

技術規格:

-

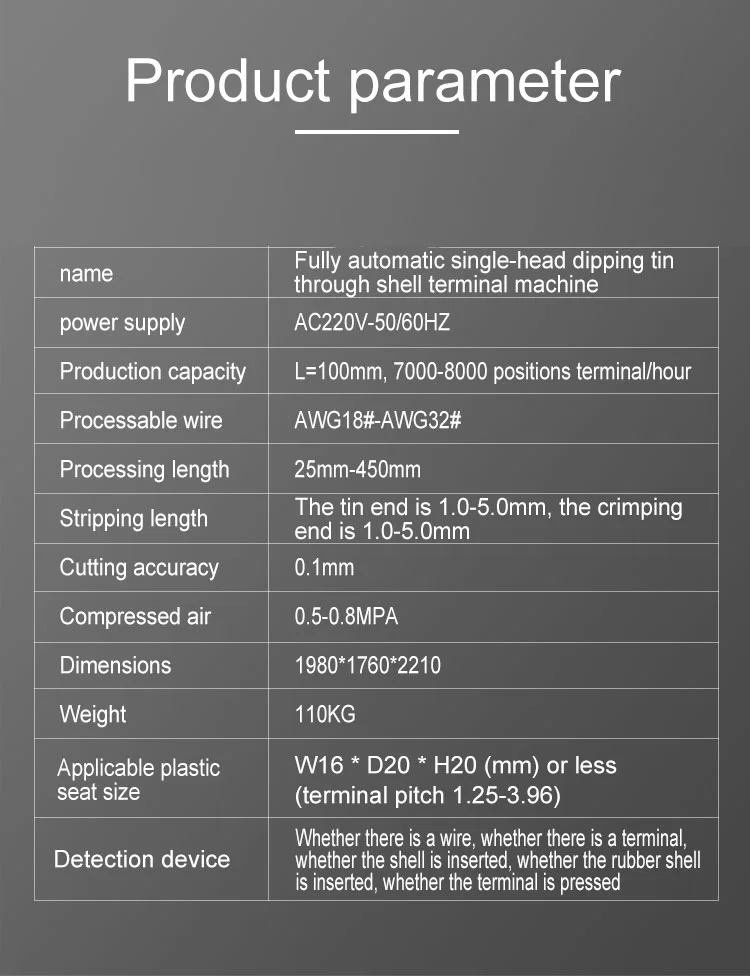

Product Name: Fully automatic single-head dipping tin through shell terminal machine (Wire Dip Tin Machine)

-

Power Supply: AC220V - 50/60HZ

-

Production Capacity: L=100mm, 7000 - 8000 terminals/hour

-

Processable Wire: AWG18# - AWG32#

-

Processing Length: 25mm - 450mm

-

Stripping Length: Tin end: 1.0 - 5.0mm, Crimping end: 1.0 - 5.0mm

-

Cutting Accuracy: 0.1mm

-

Compressed Air: 0.5 - 0.8MPA

-

Dimensions: 1980mm x 1760mm x 2210mm

-

Weight: 110KG

-

Applicable Plastic Seat Size: W16 * D20 * H20 (mm) or less (terminal pitch 1.25 - 3.96)

-

Detection Devices: Wire presence, terminal presence, shell insertion, rubber shell insertion, terminal crimping quality

Transform Your Wire Processing with the Wire Dip Tin Machine Today!

The Wire Dip Tin Machine is the ultimate investment for businesses seeking to optimize their 2P parallel wire processing. Achieve unmatched automation, precision, and quality in your wire harness production. Contact us now to discover how this revolutionary machine can transform your production line and provide you with a significant competitive advantage in the market for Wire Dip Tin solutions!

English

English Malay

Malay Swedish

Swedish Finnish

Finnish Danish

Danish Norwegian

Norwegian Polish

Polish Greek

Greek