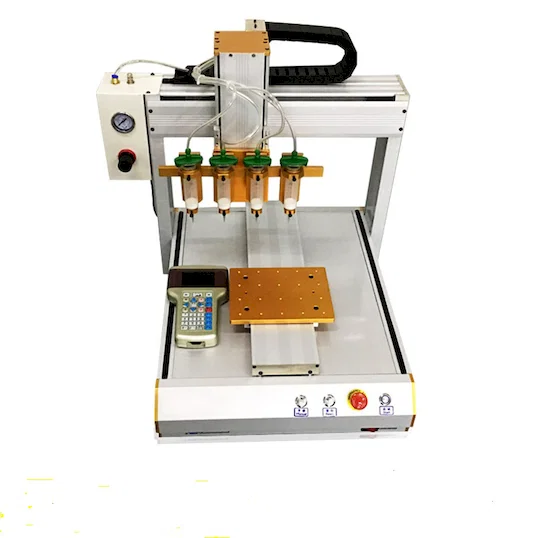

自動四軸旋轉點膠機器人 圓弧面塗膠

規格參數

自動旋轉點膠機器人 4軸點膠機器人 高效點膠機,自動旋轉點膠機器人,4軸點膠機器人,點膠機1.可以用不同平面或曲面上的點、條紋、弧和圖案的高精度程式設計來代替手動作。2. 適合定位不同的工作。3. 支援從計算機導入的圖形、PLT 檔、TCF 檔案和 G 代碼檔。4、適用於膠水:厭氧、塗料、氰基丙烯酸酯、白膠、環氧樹脂、油脂、密封劑、矽膠、焊料/釺焊膏、導熱矽脂、導電膠、紅膠、UV膠、AB膠、聚氨酯樹脂膠等。本設備適用於高效率、高運行精度、點膠的生產過程。一般適用於產品用感測器、繼電器、電源適配器、電子玩具、發聲器、電子元件、家用電器、電動車控制器、電腦數碼產品、工藝品、手機板、線圈產品、紐扣產品、電池盒、揚聲器點膠粘接;揚聲器封裝點膠、光學半導體、手機電池、筆記本電池封裝、PCB板粘接、COB、IC、PDA、LCD封口、IC封裝、IC粘接、機箱粘接、光學器件加工、五金零件封裝塗布、定量注液、晶元貼裝、汽車機械零件塗裝、機械密封等。- 立即詢價

English

English Malay

Malay Swedish

Swedish Finnish

Finnish Danish

Danish Norwegian

Norwegian Polish

Polish Greek

Greek